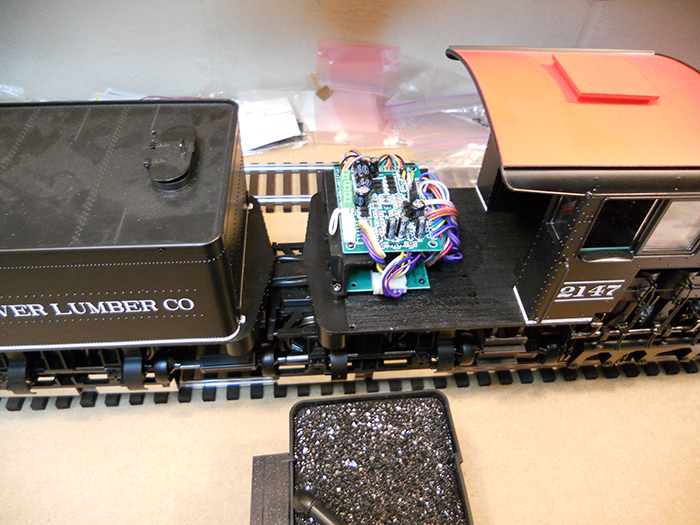

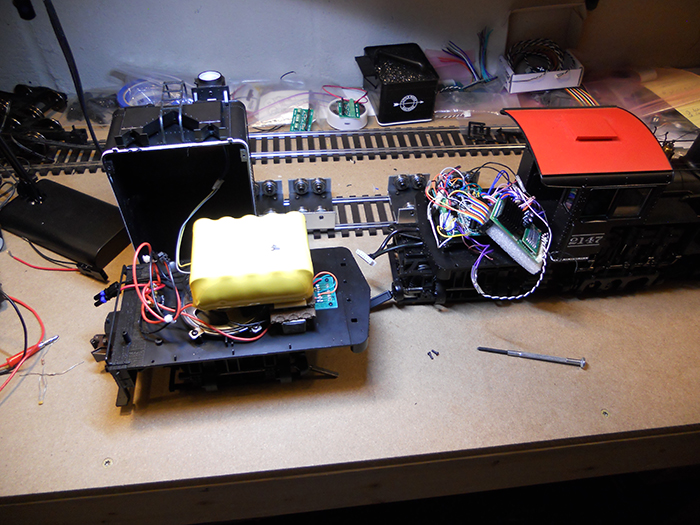

The battery pack goes in the water tank part of the Shay. The original speaker is also in the water tank, and remains there. Since wiring between the water tank and main unit was already in place, i used it - just reassigned what the wires were used for. All of my battery packs are 18.5V lithium ion. My preferred size is 9000mAhr, but that would not fit in the water tank. So I had to settle for the 6000mAhr size here (that number means the battery will put out 1 amp for 6 hours, or 6 amps for 1 hour, or something in between). I anticipate getting at least a couple of hours out of the Shay pulling a load, but also prepared for backup.

All of my battery cars and battery tenders have the battery pack, a switch, and a plug on the trailing end. The switch selects off/recharge, run on internal battery, or run on external battery. The 'external' setting means feed power from a trailing car through to the locomotive. The internal setting means run on the battery in the tender. The off position disconnects the battery from the locomotive. But in the off position, I can also connect the 'smart' battery charger to recharge the battery without opening the tender up.

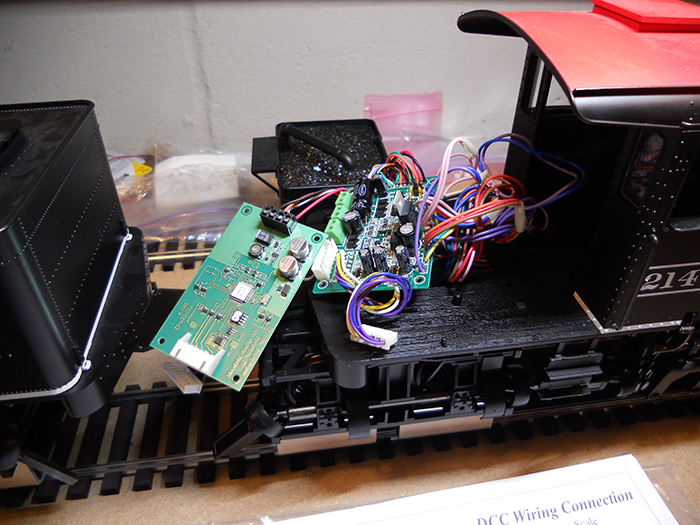

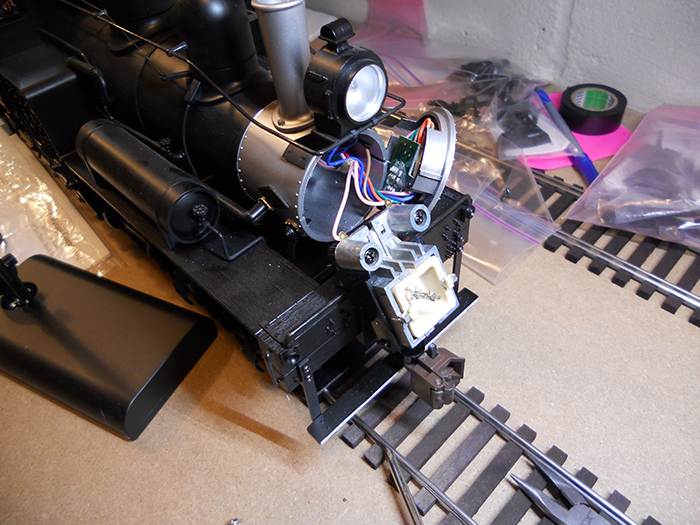

I added the magnetic whistle sensor to the Shay just as I was doing with all the other retrofits. I went looking for the chuff sensor and could not find anything documented. But there were a couple of undocumented mystery wires that seemed to be coming from somewhere in the middle of the drivetrain. With a little bit of testing, I discovered that these did in fact form contact closures whose rate seemed proportional to the speed of the loco. But when I connected these wires to the control board, I found out why they were undocumented. They were chuff sensors, but of such bad quality, Bachmann didn't want you to know about them. The loco sounded like it had a bad stuttering problem.

The Crest board does have the ability to "fake it" if there is no chuff sensor. It will vary the rate of the sound as speed is varied. It just won't be synchronized exactly with train speed. I have seen a variety of after-market chuff sensor retrofits, and may add this at some later time.

The public debut of not only the Shay, but the layout, was the Minnesota Garden Railroad Society open house Aug. 28, 2016.